- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 24 Author: Site Editor Publish Time: 2024-04-28 Origin: Site

In the realm of dentistry, the utilization of static mixers is paramount for various dental procedures. These mixers play a crucial role in blending dental materials to achieve the desired consistency and properties. This article delves into the intricacies of dental static mixers, elucidating their disparities compared to standard static mixers.

Dental static mixers serve as indispensable tools in dental treatments, facilitating the thorough mixing of materials crucial for procedures such as composite fillings and impression taking. Unlike manual mixing methods, static mixers ensure uniform blending and eliminate air pockets, thereby enhancing the quality and longevity of dental restorations.

Standard static mixers, commonly used in various industries, operate based on a simple yet effective principle. They consist of stationary elements within a mixing chamber, which disrupt and blend incoming materials as they flow through. In industrial settings, these mixers are employed for tasks ranging from chemical processing to food production.

Dental static mixers are typically crafted from materials that meet stringent medical-grade standards. Common options include biocompatible plastics and corrosion-resistant metals like stainless steel. These materials ensure compatibility with dental materials and patient safety during procedures.

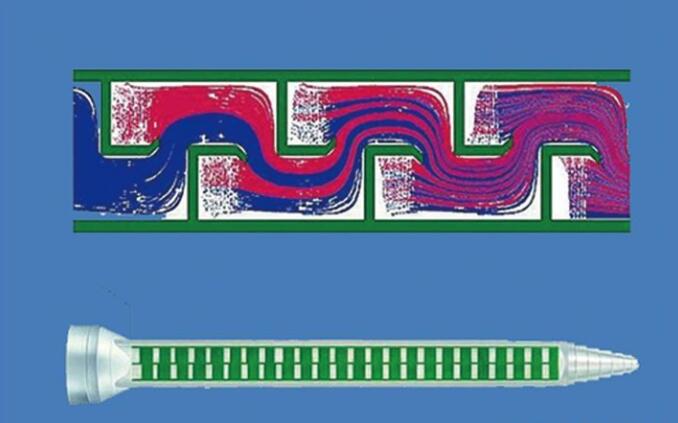

The design of dental static mixers incorporates features tailored to the intricacies of dental procedures. For instance, the tip design may be optimized for precise material application, while the mixing chamber shape enhances thorough blending without compromising flow properties.

Given the critical importance of hygiene in dental practice, dental static mixers are subject to rigorous cleanliness standards. They must be easily sterilizable and resistant to chemical disinfection methods to prevent cross-contamination and ensure patient safety.

One notable disparity between dental static mixers and standard static mixers lies in their structural design. While standard static mixers are designed for general industrial applications, dental static mixers are purpose-built with features optimized for dental procedures. These include specialized tip designs and mixing chamber configurations tailored to the specific requirements of dental materials.

Another key difference is evident in the selection of materials and hygiene requirements. Dental static mixers prioritize biocompatibility and sterilizability due to their direct contact with oral tissues and dental materials. In contrast, standard static mixers may prioritize factors such as chemical resistance and durability for industrial environments.

In the context of composite fillings, dental static mixers play a pivotal role in ensuring the thorough blending of resin and catalyst components. The precise tip design allows for controlled dispensing of the mixed composite material directly into the cavity, ensuring optimal adaptation and minimal voids. This results in durable and aesthetically pleasing restorations.

During impression taking for dental prosthetics, such as crowns and bridges, the accuracy of the impression material is paramount. Dental static mixers facilitate the homogeneous mixing of impression materials, ensuring uniform consistency and precise reproduction of the oral tissues. This contributes to the fabrication of accurately fitting dental prostheses, ultimately enhancing patient comfort and satisfaction.

In summary, dental static mixers offer several advantages over standard static mixers in dental practice. Their specialized design and material selection cater to the unique requirements of dental procedures, ensuring optimal performance and patient safety. By facilitating efficient mixing and precise dispensing of dental materials, these mixers contribute to the success and longevity of dental restorations and prostheses.

In conclusion, dental static mixers represent a specialized category of static mixers tailored specifically for dental applications. These mixers exhibit distinct characteristics and design features that differentiate them from standard static mixers used in industrial settings. With their focus on material compatibility, hygiene requirements, and procedural optimization, dental static mixers play a crucial role in ensuring the success and longevity of various dental treatments and procedures.

Looking ahead, the field of dental static mixers is poised for further advancements and innovations. Continued research and development efforts aim to enhance mixer performance, expand material compatibility, and streamline procedural workflows. As technology evolves, dental professionals can expect to benefit from increasingly sophisticated static mixing solutions that further elevate the standard of care in dentistry.

As dental practices continue to evolve, the adoption of specialized tools and equipment, such as dental static mixers, remains integral to delivering optimal patient outcomes. Dentists and dental technicians are encouraged to stay informed about the latest developments in static mixing technology and incorporate these advancements into their practice to uphold the highest standards of patient care and treatment efficacy.

Phone: (+86)-133-3268-9021(Mark Li)

Email: sales@gluecartridges.com

ADD: Dongguan, Guangdong, China.

Haijing Company A Sindesun Company

All Rights Reserved